| HOME > PRODUCT > Centrifugal pump > Volute pump |

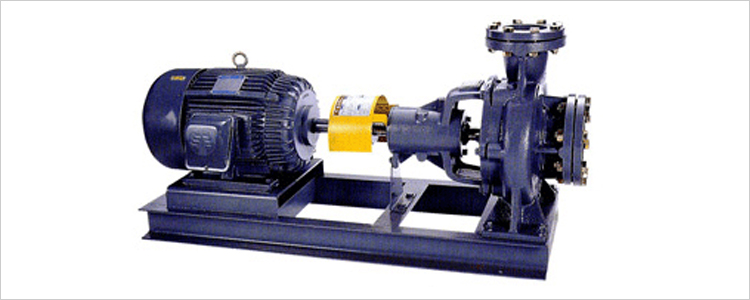

| Volute pump |

|

Special Pump Total Maker "ILSUNGPUMP" |

| |

|

|

| |

|

| |

|

| |

| Standard spec |

| Item |

1750rpm |

3500rpm |

| Max Flux range

(㎡/min) |

0.1~7 |

0.2~6 |

| Max lift (m) |

5~60 |

8~85 |

| Use temp range (℃) |

Clear water 0~90 degree |

| Allowable Suction Press (kg/㎠G) |

|

| Rotation direction |

CW |

| Max suction lift (m) |

-6 ~ -7(20℃ basic) |

| PLANGE |

Rating |

KS10kg/cm2 |

| Facing |

RF FF |

| Structure |

Impeller |

CLOSE(OPEN) |

| Packing unit |

GLAND / P,M / Seal |

| Bearing mode |

Ball B /R |

| Flange position |

Suction flange |

END SUCTION |

| Discharge flange |

TOP DISCHARGE |

|

| |

| Characteristics |

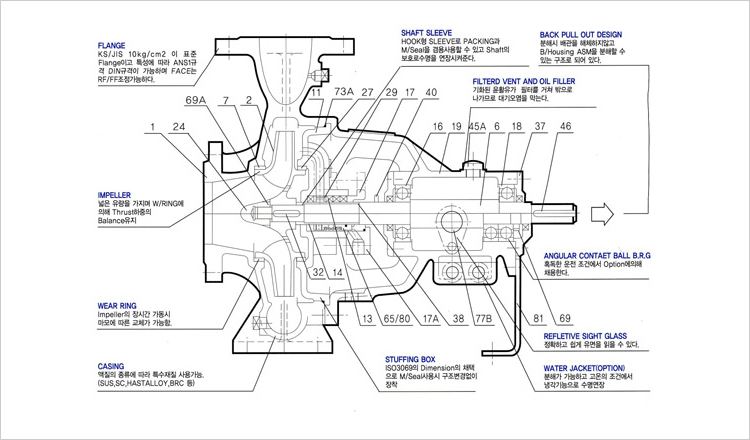

| Applied standard |

- ISO 2858(international standardization norm)

- KS b7501(korea standard norm)

- JIS b8313(japan standard industry norm) |

| |

| Characteristics |

- wide use range with flux lift’s standardization

- with unification of dimension, the same dimension to other companies’ products

- possible to use special material according to the kinds of liquid (sus, sc, hastelloy, brc)

- with the standardization of parts, keeping the highest compatibility

- because discharge diameter is placed in the top of center, keeping the piping load’s stability and balance maintenance in running.

- with back pull out structure, at the time of disassembly, possible to work without dismantling of equipment piping

- possible to use packing and m/seal according to applications |

| |

| Applications |

|

| |

| General industries(seawater, chemical liquid, oil, alkali, industry water) chemical industry(acid-resisting), water for home, water supply equipment and water for building disposal, air-conditioning/heating circulation, water for irrigation and ship, spring cooler, for hygiene, water for farming, etc |

|

- Chemical Industry

- Petroleum Relineries

- The Petrochemical Industry

- Other Various Industries |

| |

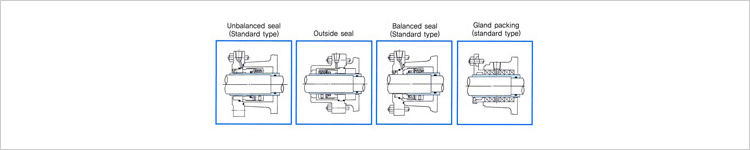

| Mechanical seal device |

|

| |

1. By using M/SEA TYPE, protecting the leakage.

2. M/SEAL TYPE reduces the power consumption remarkably to 1/3-1/6 that that of packing type. |

| |

| Stuffing box |

| Related standards |

- By applying ISO3069 dimension, in using M/seal, it is easy to fix without structure change and simple in maintenance/ repair

- Standard dimension compared to overseas or other company’s m/seal. (international standardization) |

| |

| Materials |

- STS-304, 316

- Alloy 20(durimel20)

- Cast iron(GC20)

- HASTELLOY B/C/D

- Cast Steel(SC46)

- Ductile Cast iron(GCD) |

|

| |

| Flange |

| Applied standard |

- KS JIS 10kg/㎠

- Possible to manufacture by order for other, international standard

△ANSI Standard △DIN Standard, BS △KS 5~20kg/㎠ |

| |

| Symbol and mark |

|

| |

| NAME OF PART & MATERIAL |

| NO |

NAME OF PART |

MATERIAL |

| CLASS1 |

CLASS2 |

CLASS3 |

| 1 |

CASING |

GC200 |

SSC13 |

SSC14 |

| 2 |

IMPELLER |

GC200 |

SSC13 |

SSC14 |

| 6 |

SHAFT |

SM45C |

STS304 |

STS316 |

| 7 |

CASING RING |

BC6 |

SSC13 |

SSC14 |

| 11 |

STUFFING BOX |

GC200 |

SSC13 |

SSC14 |

| 13 |

PACKING |

TEFLON |

TEFLON |

TEFLON |

| 14 |

SHAFT SLEEVE |

STS304 |

STS304 |

STS316 |

| 16 |

INBORD BEARING |

STEEL |

STEEL |

STEEL |

| 17 |

PACKING GLAND |

GC200 |

SSC13 |

SSC14 |

| 17a |

M/SEAL COVER |

GC200 |

SSC13 |

SSC14 |

| 18 |

OUTBOARD BEARNG |

STEEL |

STEEL |

STEEL |

| 19 |

BEARING HOUSING |

GC200 |

GC200 |

GC200 |

| 24 |

IMPELLER NUT |

SM45C |

STS304 |

STS316 |

| 27 |

STUFFING BOX RING |

BC6 |

SSC13 |

SSC14 |

| 29 |

LANTERN RING |

TEFLON |

SSC13 |

SSC14 |

| 32 |

IMPELLER KEY |

SM45C |

STS304 |

STS316 |

| 37 |

BEARING COVER |

GC200 |

GC200 |

GC200 |

| 38 |

SLEEVE GASKET |

RUBBER |

NBR |

TEFLON |

| 40 |

DEFLECTOR |

RUBBER |

NBR |

NBR |

| 45A |

OIL CAP |

PLASTINC |

PLASTIC |

STEEL |

| 46 |

COUPLING KEY |

SM45C |

SM45C |

SM45C |

| 65/80 |

MECHANICAL SEAL |

TC/CA |

TC/TC |

SIC/SIC |

| 69 |

VEARING LOCK NUT |

SM45C |

SM45C |

SM45C |

| 69A |

LOCK WASHER |

SM45C |

- |

- |

| 73A |

CASING GASKET |

RUBBER |

NBR |

TEFLON |

| 77B |

OIL GAUGE |

PLASTIC |

PLASTIC |

GLASS |

| 81 |

SUPPORT |

SS41 |

SS41 |

SS41 |

|

| |